Safety Guidelines for Machine Lifting

Various risks come with machine lifting. Therefore, it's important for safety measures to be taken during this operation. Projector Lifting Service Ltd is well aware that this activity requires intensive management. This will involve experts and professionals who have the commitment and resources to handle this task.

Operating Lifting Machinery

Lifting objects mostly takes place at construction sites, shipyards and factories. It is also done at other industrial operations during offloading with a forklift truck, containers at a warehouse or commercial area. Incorrect lifting methods can be very dangerous because it can lead to accidents, resulting in damages and injury.

It is possible to move large objects without causing any damage or accidents if the right measures are put into place. For safe lifting to happen, it is important to put some things into consideration when planning and during the lifting operations. The guidelines about safe lifting operations in workplaces must be followed according to the Code of Practice (CP).

How to Calculate Lifting Safety Factors

Firstly, you must identify the lifting capacity of your machine. The lifting capacity refers to the maximum weight the machine can safely handle. Failing to adhere to this may cause serious damage to the machinery or an accident that could lead to injury.

The calculation is done by multiplying the impact allowance factor by the load capacity of the main wheels. You need to determine the combined weight of the trolley and the hoist. To work this out, you must combine the weight of the trolley and the hoist of the machine, in tons, and divide by the common factor of 2.

For example, the main wheel that provides a load capacity of 100 tons and an i mpact factor of 1.15 would give 115. If you divide this number by the common factor of 2 in this example, you will get a total of 57.5. If you add this number to the answer from step one, the equation would be 57.5+(2/2) =58.5.

Step 3 is dividing the total weight of the machine in use, by the common factor of 4. This is then added to our previous answer. The machine weight should be measured in tons to make sure that we have an accurate calculation. If you are calculating the lifting capacity of a machine that weighs 4 tons, the equation would be 58.5+(4/4) =59.5. The total lifting capacity of the machine is 59.5tons.

Scope of The Guidelines

The guidelines explain the key responsibilities involved in lifting machines; they are also set to give guidance to the organisation at large. These guidelines are set to help in assessment, planning, implementation and management of change and development of safety in machine lifting operations.

The guideline document is used as a tool to aid the consideration of safety measures when carrying out the lifting activities for the managers, the personnel handling the machine and the employees. Therefore, it is the responsibility of those hiring or using the lifting machines to ensure all the specific measures for safety in machine lifting are followed as outlined in the guidelines.

Objectives

One of the objectives of improving safety during lifting operation is planning, which should apply to all workplaces according to the Health and Safety at Work Act (HASAWA). Planning also helps to identify the causes of risks, as well as identifying the best measures to reduce them, avoid damage and improve safety in the workplace.

The communication process is also vital when setting up safety objectives. Poor communication between responsible persons leads to loss of important information which is fundamental for safe operation at the workplace.

Site Survey

The load must be surveyed to be lifted, and the entire project must be analysed. This will aid the knowledge of the type of work to be expected, using important factors such as:

- Weight

- Size

- The ground conditions

- The location the load needs to be lifted from

- The route that needs to be used

The person performing the survey should be well qualified and have a wide range of experience. This is to ensure the report given for the survey is accurate and helpful in ensuring safety.

Risk Assessment

The main aim of a risk assessment is to prevent accidents and damages that may arise during the operation. The site survey is an important factor of the risk assessment. It also helps in the implementation of safety measures using the principle of control hierarchy.

Examples of tasks that could cause risk during operation include:

- Excavations

- Narrow access

- Pipe racks

- Overhead structures

- Other plant operating in the vicinity of the lifting

After risk assessment, it is crucial for safety measures to be implemented. All the hazards identified during the site and risk assessment must be removed, and control measures must be put into place for better working conditions.

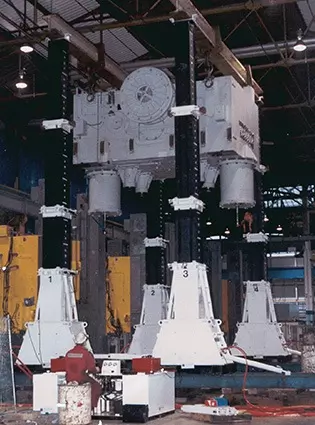

This guideline for safe machine lifting was created to help you to lift heavy machinery safely in the workplace. Projector Lifting Service Ltd have over 159 years of experience in heavy machinery lifting and relocation. We can help you plan a safe and efficient moving of your factory machinery. Our range of lifting equipment and experience means that we can move anything from generators, transformers and injection moulding machine to Euro shuttle and Crematoria. Get in touch for your free quotation for heavy lifting between 20-453 Tonnes or a bespoke contract lifting service.

If you need to find a company that you can trust to manage your machine lifting safely, follow the link below.